Search This Blog

This is a blog about the adventures of building my split-level house and making it into a home.

Posts

Showing posts from August, 2008

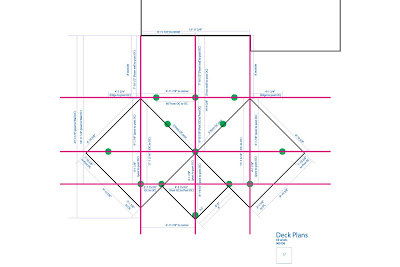

Deck - Last 2 Piers Done, Constructed Main Level Supports

- Get link

- Other Apps

Deck - Last 2 Holes Dug, 4 More Piers Poured

- Get link

- Other Apps

Deck - Lumber & Material Delivery

- Get link

- Other Apps

Deck - Ordered Hidden Deck Fasterners

- Get link

- Other Apps